by Scott Ammerman

Senior Torque Correspondent

An anti-roll bar, also commonly referred to as a sway bar, reduces body roll by limiting excessive suspension travel while cornering.

This device is commonly found on most modern vehicles, sometimes in both the front and the rear. Due to the high roll center of Jeeps and SUVs in general, all currently produced Jeep vehicles come equipped with them right from the factory.

In a situation where the body would want to gravitate to the outside of a turn at even moderate speeds, the sway bar limits suspension travel and attempts to keep the wheels closer to parallel with the body. For the purposes of this article, we are going to primarily focus on the JK Wrangler’s sway bar system, although most other Wrangler generations are strikingly similar.

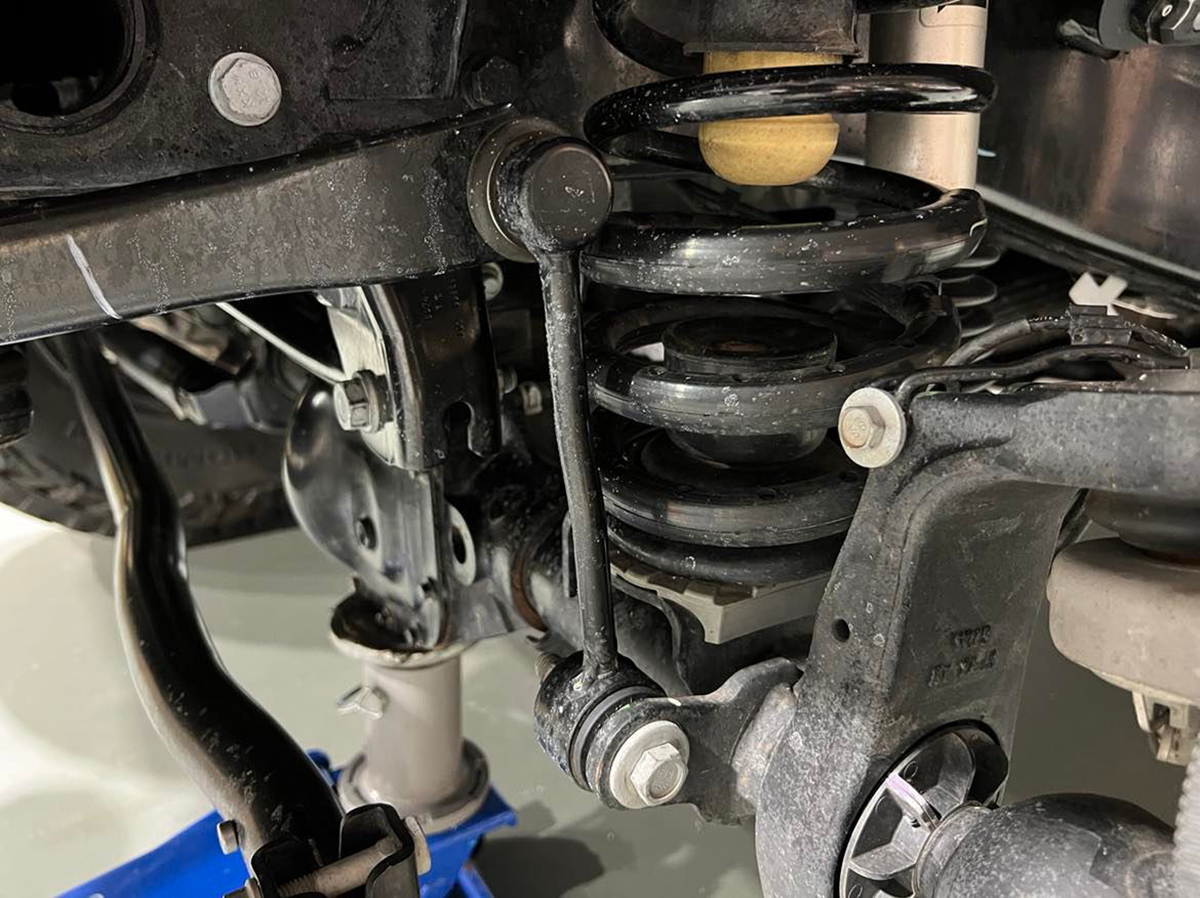

The front sway bar (figure 1 in this picture) is attached to both frame rails in the center using a rubber bushing assembly (figure 3), which prevents vibration from being transmitted into the frame while allowing the bar to rotate. The sway bar end links (figure 2) are bolted to the axle housing at two mounting points, one on either side.

On many other vehicles, including Jeeps not equipped with a solid front axle, these end links would attach to the lower control arms.

So now that we understand the concept of a vehicle’s sway bar, why on earth would anyone want to remove or disconnect it?

Off road, when traveling at lower speeds, the sway bar assembly is actually detrimental to both suspension travel and occupant comfort. Because it is designed to limit excessive suspension movement in relation to the vehicle’s frame, it also keeps the entire axle assembly from being able to articulate to get over obstacles.

When this occurs, the suspension is fighting against the sway bar’s efforts to keep the axle parallel with the underside of the frame — and anyone inside the Jeep will feel the struggle as they are rocked back and forth with every bit of uneven terrain.

A dip in the trail can cause one tire to drop several inches below the other, with the sway bar working to resist the torsion in the center and trying to keep both wheels in line with each other. A slight rise with the sway bar equipped, and your opposite side tire can actually end up in the air, robbing you of traction.

With a properly disconnected sway bar, the front axle is able to “float” under the frame, allowing more travel than it would have with the system functioning as it does on the road. This also keeps more of your tire’s tread in contact with the earth, increasing your ability to gain traction.

Because of this, many people who own Jeeps strictly for trail use only tend to fully remove (or as some would say “delete”) their sway bars to increase suspension travel. While you can certainly drive on the road without a sway bar for short distances, a Jeep with a raised suspension — and higher roll center — will always benefit from a sway bar in most road conditions.

Jeep Wrangler Rubicon JK, JL and JT models also come with an electronic disconnect sway bar system as standard equipment, allowing drivers to gain these advantages simply with the push of a button when going off-road. Then, when coming off the trail, the sway bar can be reattached with that same button.

But if you do not have a Rubicon edition, how can you gain these benefits when tackling more challenging terrain?

Well, you could simply remove your sway bar end links and their associated bolts before venturing onto the trail. However, this can be time-consuming if you are a frequent off-roader, so most people opt for a quicker solution.

Sway bar disconnects are the most cost-effective way to disconnect your front sway bar before off-road use. This popular set, made by JKS, allows you to fully remove the link by removing two pins. With your Wrangler on a level surface, this can be accomplished in a matter of minutes.

These JKS disconnects come in two varieties for the JK, 0-2 inches of lift and a longer and more adjustable version for vehicles with 2.5-6 inches of lift. Installation only requires removal of the factory links and their mounting bolts, which are then replaced with polished finish pins that hold the replacement links. The length must be set to accommodate your vehicle’s ride height, but detailed instructions provided with the kit make installation a snap.

They also feature greaseable polyurethane spherical bearings to ensure silent and trouble-free performance.

Rather than full removal, this Synergy Manufacturing Front Sway Bar Disconnect kit for '07-'18 Wrangler JK vehicles with 3-4.5 inches of lift allows you to merely remove the lower connection, and rest the disconnected link on an included frame mount bracket. This kit does require drilling into your frame to mount the brackets, but it is not a lot of work with the right tools.

Do you keep your Jeep “trail ready” at all times? RockJock manufactures several varieties of AntiRock off-road sway bar replacements that are more forgiving during tire articulation. These come in aluminum and steel, and are offered for several different chassis designations — from the Commanche/XJ Cherokee, up through the TJ and LJ Wrangler and the JK lineup as well. The trade-off is they are more forgiving on the street as well, countering vehicle sway more than no sway bar at all, but less than a factory unit.

And what if you do want that Rubicon “pushbutton” style electric disconnect on your Sport or Sahara JK or JK Unlimited?

Well, we’ve got you covered with the “top of the line” G2 Axle & Gear 72-2050DRS Core Dual Rate Sway Bar System. This handles on-road situations better than the factory configuration, with a three-position adjustable primary spring rate, and a second much softer rate available at the push of the button for trail use.

This system does not limit front suspension travel in the slightest, even while remaining fully connected to the axle — even on highly modified Jeeps. The disconnect is air actuated, and we’ve covered two different types of installations already.

For air systems with an onboard compressor, we have this video featuring an installation on Overkill.

For Power Tank CO2 systems supplying the pressure, here is my installation on project Rattler.

For troubleshooting tips with a JK/JKU Rubicon sway bar that is giving you issues, or information on installing an EVO Manufacturing NoLimits Manual Sway Bar Disconnect System, here is some information from the now-retired Project Rattler.