The Extreme Short Shaft kit is what short wheelbase Wrangler owners have been dreaming of for decades. The Extreme kit not only improves on strength, but also increases driveshaft lengths by up to 7" over a stock application. It is over 3" shorter than a standard SYE kit, and 1-1/2" shorter than an ATLAS II. The Extreme SS kit comes with all necessary components to modify the stock 231 case. Speedometer readings are transferred through a tone ring and electronic sensor. To adjust the calibration a converter box is necessary to make any calibration adjustments.

Note: Requires a longer CV driveshaft, which is sold separate

SLIP YOKE ELIMINATORS - 101

Most 231 transfer cases came from the factory with a slip-yoke rear output (see bottom photo). This slip yoke will slide or slip in and out of the rear of the transfer case as the suspension cycles up & down. When driveshaft angles are changed due to suspension height or suspension travel the slip yoke is forced to operate at an angle and can cause binding, and in some situations will crack the case.

Another problem with the slip yoke design is that the rear driveshaft yoke cannot be removed from the vehicle without loss of transfer case fluid.

Broken u-joints can often require the vehicle to be driven back off the trail with the front driveshaft only. Without eliminating the slip yoke on the

rear output, this would be impossible without losing the transfer case fluid, and causing transfer case damage.

On any short wheel base vehicle (such as the Wrangler), driveshaft angle is very critical and

must be addressed when making any suspension modifications. Standard factory Wrangler

driveshafts are about 12". This short driveshaft will cause severe vibration and premature u-joint failure if not upgraded.

A Short Shaft kit, or Slip Yoke Eliminator solves the short driveshaft length, allows driveshaft removal in the event of a u-joint failure without loss of fluid, and increases the output shaft strength dramatically allowing for increased

power and torque to be transferred to the wheels for traction.

There are several approaches to Slip Yoke Eliminator kits. Some use a "hack & tap" method which results in a lower priced kit, but does not effectively increase any strength, and can actually increase driveshaft vibration. TeraFlex was one of the innovators that developed a completely new heavy duty output shaft that can increase

torque loads by nearly 50%, as well as offer solutions to the original slip yoke problems. TeraFlex has perfected low range gearing and continues to lead the industry in quality performance transfer case products.

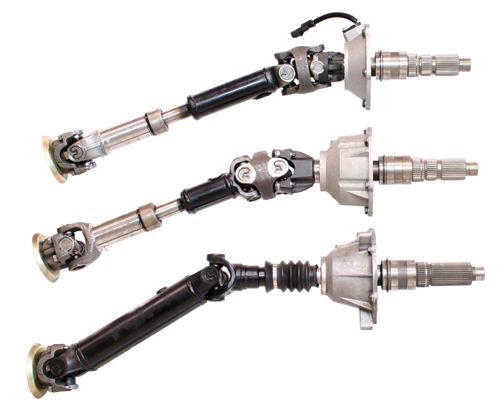

Top Photo: Extreme Short Shaft SYE

Middle Photo: Standard Short Shaft SYE

Bottom Photo: Stock Slip-Yoke

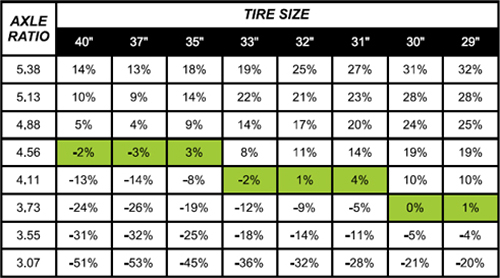

The Extreme Short Shaft kit does not use the traditional "speedometer gear" to

calibrate the speed of the vehicle. We have updated the signal to a digital reading

(similar to 03+ Rubicon). This allows a more accurate reading. The chart below

gives you the configuration of your vehicle by comparing tire size and axle ratio.

If your selection of tire size and gear ratio do not yield a result that is within the

green acceptable range a converter box will be necessary to make any calibration

adjustments.

An accurate speedometer reading is important both on and off road when detailing

travel routes and for on highway safety.

Factory speedometer variances are Ã?�Ã?±3% from actual speed. Recommended

speedometer driven gears are based on a manufacturer's published tire specs for

revolutions per mile. This may differ from manufacturer to manufacturer.

Extreme Short ShaftSpeedometer Calibration Chart

Fits 231-J transfer cases only

Earlier 231 applications with mechanical speedometer cable require updating to an electronic speedometer.

Output Shaft

Output Housing

Speed Sensor Ring

Bearing

Seal

Yoke & Nut

Installation Hardware

- Transfer Case Model: NP231

- Shipping Weight: 15lb

- Shipping Dimensions: 16in x 12in x 6in (L x W x H)

Jeep Cherokee (XJ)

- 2001 Jeep Cherokee (XJ)

- 2000 Jeep Cherokee (XJ)

- 1999 Jeep Cherokee (XJ)

- 1998 Jeep Cherokee (XJ)

- 1997 Jeep Cherokee (XJ)

- 1996 Jeep Cherokee (XJ)

- 1995 Jeep Cherokee (XJ)

- 1994 Jeep Cherokee (XJ)

- 1993 Jeep Cherokee (XJ)

- 1992 Jeep Cherokee (XJ)

- 1991 Jeep Cherokee (XJ)

- 1990 Jeep Cherokee (XJ)

- 1989 Jeep Cherokee (XJ)

- 1988 Jeep Cherokee (XJ)

- 1987 Jeep Cherokee (XJ)

- 1986 Jeep Cherokee (XJ)

- 1985 Jeep Cherokee (XJ)

- 1984 Jeep Cherokee (XJ)

Jeep Wrangler (TJ)

- 2006 Jeep Wrangler (TJ)

- 2005 Jeep Wrangler (TJ)

- 2004 Jeep Wrangler (TJ)

- 2003 Jeep Wrangler (TJ)

- 2002 Jeep Wrangler (TJ)

- 2001 Jeep Wrangler (TJ)

- 2000 Jeep Wrangler (TJ)

- 1999 Jeep Wrangler (TJ)

- 1998 Jeep Wrangler (TJ)

- 1997 Jeep Wrangler (TJ)

Jeep Wrangler (YJ)

- 1995 Jeep Wrangler (YJ)

- 1994 Jeep Wrangler (YJ)

- 1993 Jeep Wrangler (YJ)

- 1992 Jeep Wrangler (YJ)

- 1991 Jeep Wrangler (YJ)

- 1990 Jeep Wrangler (YJ)

- 1989 Jeep Wrangler (YJ)

- 1988 Jeep Wrangler (YJ)

- 1987 Jeep Wrangler (YJ)

Jeep Wrangler Unlimited (LJ)

- 2006 Jeep Wrangler Unlimited (LJ)

- 2005 Jeep Wrangler Unlimited (LJ)

- 2004 Jeep Wrangler Unlimited (LJ)

- Shared By Others

- Share a Photo

- Ask a Question

- Write a Review

Teraflex 231 Extreme Short Shaft Kit Reviews

I'm giving this 3 stars for a few reasons: One, on step 29 of the manual (Rev. 21) you'll see: "The [u-joint retainer] bolts must be inserted into the yoke prior to yoke installation or they will not fit!" I didn't catch that when I bought it, and I really don't like the idea of the u-joint bolts being captured where you have to pull the yolk if they strip or break. I'm going to go with u-bolts for this reason, hopefully that works out okay. This is my main gripe with this kit, I think shaving the yolk to the point the bolts can't be replaced is a step too far.

Also, reinstalling the front yolk requires a non-reusable seal between the front yolk and shaft. This kit didn't come with that seal. Fortunately I was overhauling at the same time (which I recommend, you have to do half that job anyway to install the kit) and the overhaul kit had the missing seal.

This kit also uses a tiny dowel pin to hold the tone-ring to the output shaft. If that pin seizes it will be extremely difficult to disassemble the transfer case as the oil pump won't be able to some off the shaft. It should be bathed in ATF so hopefully I'm worrying about nothing here, but that was something that made me nervous during the install. Fingers crossed on that one.

Otherwise it is a good kit with clear instructions. All the new bearings and seals were pre-installed so reassembly was easy. Note the torque on the front yolk before starting, it's over 200 ft/lbs. We needed to use a 3/4" torque wrench for that, which is not a tool that comes out very often, and a way to hold the yolk. Also make sure you have a good pair of snap ring pliers to get the unit apart, there are many YouTube videos about this that can show you the kind of snap rings you'll be up against.

One final note to know about: the rear bearing is a ball-bearing that's pre-installed in the new housing and open on the inside so the transfer case oil can lubricate it. Because of this it's shipped in a cardboard box inside the main box, where any dirt or water that gets into the box can get into the bearing as it is not sealed in plastic. I did not receive a ship notification and the box was left out in the rain. If you receive packages in a way where they might be exposed to the elements beware of this.

Questions