Every road legal, daily driven vehicle has tires on it. Not many people put any thought into the construction of the tire beyond it's dark, rubbery appearance. The following is an explanation on the two most standard tire types available today; Radial tires and Bias ply tires. There are other types of tires available for older, more antiqued cars that use inner-tubes within the tire. Much like those of a bicycle.

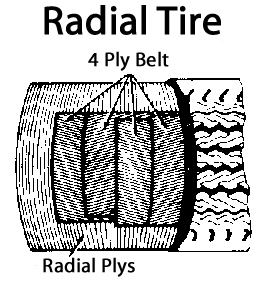

Radial Tire – A radial tire has a series of cord plies that are arranged at a 90 degree angle to the direction of tire travel. These plies of cord give the tire it's reinforcement to be able to with stand the internal air pressure and external weight of the vehicle. These network of chords that gives the tire it's strength is called a Carcass. Commonly used materials for the cords are polyester, steel, and other textile materials, inlaid with several layers of tire rubber.

If the tire was manufactured with only radial cords, it would be unable to sufficiently contact the ground due to lack of rigidness. To counter this, the entire tire is wrapped with additional belts made of steel (steel-belted radial), Polyester, or Aramid fibers (i.e. Twaron and Kevlar).

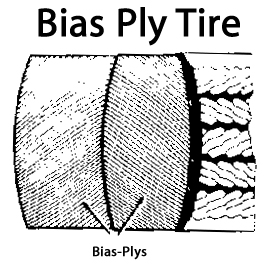

Bias-Ply / Cross Ply Tire - A Bias-Ply tire's body utilizes ply cords that extend diagonally from bead to bead. Typically laid on a 40 to 60 degree angle with successive plies set on opposing angles to form a criss-cross pattern. It is on top of these layers that the tread is applied. The ply layers generally consist of polyester, fiberglass, or steel cords embedded into the rubber itself.

This type of design allows for the tire body to flex more easily, and allow a more comfortable ride on rough terrain. However, the design is flawed at highway speeds, by disallowing good traction and increasing rolling resistance.