If you have ever driven a lifted Jeep one thing you notice is the steering. If special care is not taken in the design the vehicle will dodge and dart whenever a bump or hole in the road is hit. This is because the drag link is either being pushed or pulled by the vertical suspension movement due to not being parallel with the trac-bar. This is commonly referred to as Bump Steer.

Lets examine the components of a typical steering set-up. The axle is supported in place by the control arms and a trac-bar on a TJ suspension. Consider the leaf springs to be the control arms in an YJ/CJ. The drag link is connected to the pitman arm and also the tire rod. The drag link is pushed or pulled by the pitman arm and in turn pulls or pushes the tie rod turning the tires of the vehicle.

The diagram below shows the parts of a Jeep TJ steering and suspension.

.jpg)

Picture provided by www.4x4xplor.com

When bump-steer occurs the suspension moves in a vertical plane and the drag link is trying to be lengthened or shortened by this movement. Since its length cannot be changed then the only way to shorten or lengthen it is to turn the wheels. Shortening it would move the wheels to the Drivers side, and lengthening would move it to the Passenger side. This is generally due to the trac-bar not allowing the axle to move side to side. Often in leaf sprung vehicles the trac-bar is removed to help hide the effects of bumper steer since it then allows the axle to move side to side. This however, creates tracking issues on the highway and sometimes this can be more dangerous than bump-steer.

Generally speaking, once a TJ is lifted the drag link and the trac-bar are no longer parallel to each other. Keeping them parallel is the key as this makes them close to being in the same plane of movement and thus they mimic being the same length through the general arcs of movement. Imagine the pitman arm and the top trac-bar mounts being the start points of an arc and they both have to keep as close to each other and in the same plane as possible. Extreme flex on the trail though may not allow this to hold true as your moving so slow on the trail you may not be notice the bump steer.

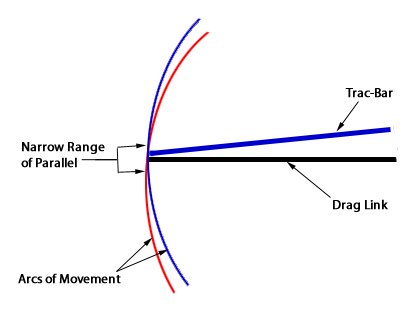

In the drawing below we see the arcs of movement created from an unparallel trac-bar and drag-link.

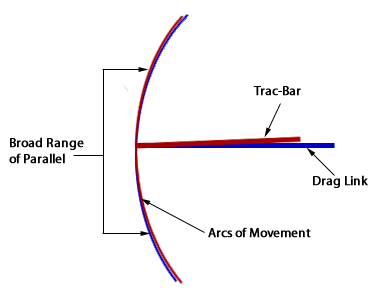

In the drawing below we see the arcs of movment created from a nearly parallel trac-bar and drag link.

Lift kits generally come with a trac-bar relocation bracket and some even suggests a dropped Pitman arm.

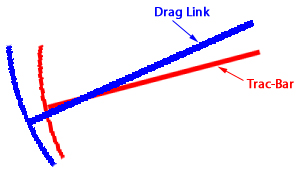

The drawing to the left illustrates a trac-bar and drag link set-up on a lifted vehicle. Notice the very uneven angles between the two creating severe bump steer.

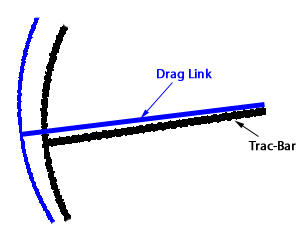

The drawing to the left illustrates a trac-bar and drag link set-up on a lifted vehicle. Notice the very uneven angles between the two creating severe bump steer. The drawing to the right illustrates the same set-up but with a trac-bar relocation bracket and a dropped Pitman arm. The two bars are now closer to being parallel than they were before.

The drawing to the right illustrates the same set-up but with a trac-bar relocation bracket and a dropped Pitman arm. The two bars are now closer to being parallel than they were before. There is no guarantee that this will cure the bump steer, as the suspension settling and the weight of passengers and cargo will alter the geometry on the highway. It will however limit the bump steer to the point of being safe to drive and not being driven into the opposing lane with every bump on the road.

With no two vehicles being alike what may work on one Jeep may not work as well on another. Please follow the instructions of the lift manufacturer and requirements for installation.