by Kyle Buchter

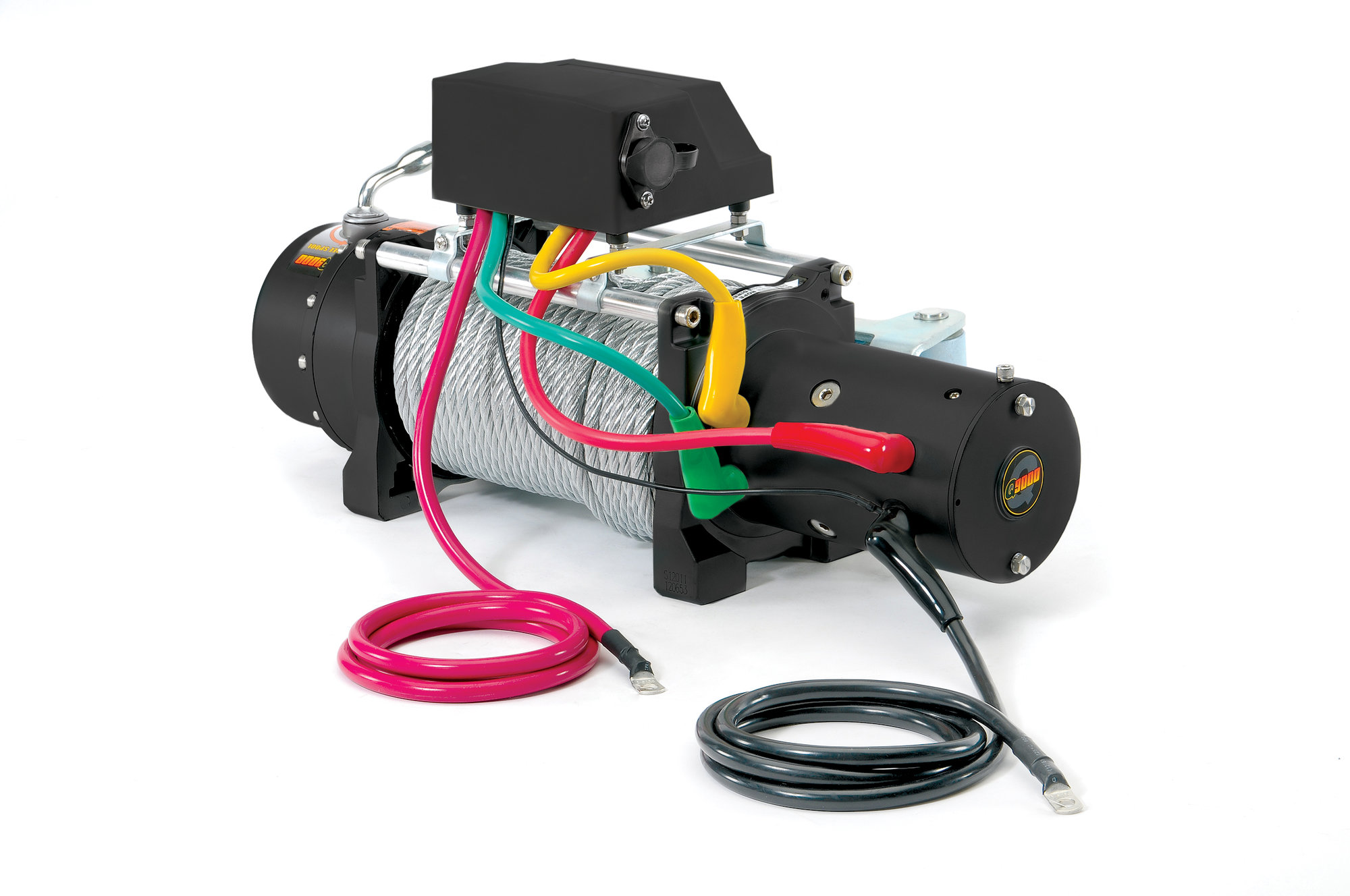

Quadratec Trail Boss

It is bound to happen at some point if you are a frequent off-roader. You are crawling down the trail and, suddenly, the Jeep in front of you skitters to the right and slides down a somewhat muddy embankment. You see the tires spinning, the mud flying, but that Jeep really isn’t going anywhere.

So you bring your vehicle up a bit, unspool your winch line, hook it up to a tow point on the other Jeep, and press the button to start your winch.

And then press it again when nothing happens. And again.

It is only then you realize the importance of winch maintenance.

Yes, time and abuse are killers of winches. Now, we are all fond of saying the quality of a winch enhances its durability, and it does to an extent. But in reality, you can get any winch to last with proper maintenance.

Brand is always a discussion when it comes to what you want in a winch. There is a reason for that. People want what they can afford but also they want it to last. Well, quality parts will only last you if you take care of them.

The best thing you can do for your winch, once it is installed, is to power it in and out a few times a year. This process gets all of the electronics cycling and makes sure there are no bad contact spots. When you do this, make sure to pull out the line about 15 to 20 feet and winch it back in. This short distance does not need to be pulled in with heavy tension, just spool neatly with a small amount of tension.

By doing this, it keeps everything in the motor and gears moving and clear. The lubrication of the gears gets cycled also which helps prevent them from drying out.

Most winches, unless you are a heavy off-road driver, can sit around for years before they are needed, only to find out they fail from dust and corrosion on the electrical components or the lubrication of the gears.

Cycling the winch at least once every few months helps prevent this. Now, we have all seen the winch on the front of someone’s grandfather’s truck that sat for 50 years blah, blah, blah, and it still works. Yes, that falls under the expression of ‘they don’t make things like they used to’.

However, do you want to trust your investment in an old theory? I know I don’t. So protect your investment. Keep all of the plug-in connectors clean and add dielectric grease if needed. Cycle the engagement lever back and forth a few times to keep everything moving.

Additionally, check all of the mounting bolts that connect the winch to the bumper, and the bumper to the frame. This is what keeps it all together so make sure all of it is still strongly attached and not compromised.

The electrical connections at the battery will need to be cleaned periodically. Just like your battery terminals, unhook the battery connections and clean them off thoroughly to make sure they are getting a good connection and current flow. Check the remote also to make sure it is working correctly and wires are in good shape.

Your fairlead should not be ignored, either. Make sure you periodically check and cleaned that opening. If you have a roller fairlead, ensure that the rollers spin freely. The center shafts can be removed from the rollers and greased to make sure they spin freely. Check that the rollers are free from rust and big gouges that could harm the cable or rope (yes you can use rollers for rope).

If it is a hawse-style fairlead, the same rules apply minus the rollers. A Scotch-Brite pad works really well for scuffing the surface to remove rope friction marks and surface rust on fairleads. Definitely keep the fairleads smooth and free from snags to preserve the line.

Winch line, whether it is synthetic rope or wire cable, needs to be maintained as well. There are plenty of articles out there about this but besides the inspection for damage and wear, you also simply need to clean them.

Cleaning is pretty simple for either one. Synthetic rope requires clean water. Pull all the rope off that winch drum and dunk it in clean water over and over until it is clean. Then, let it hang in the sun to dry. After that, winch it back on the drum under tension.

For those with cable line, there are cleaners out there, or some still use kerosene. Either work, so make your decision to clean the way you feel is best for you. Just be conscious of chemicals with environmental and health issues.

When inspecting the line for damage, there are pages and pages of different ways you can check your synthetic or wire cable. Mainly look for wear, abrasion, pulled strands, and knots for synthetic; and kinks, flat spots, and twisted and cut strands with cable.

Additionally, the hook or other attachment point at the end of your line needs to be free from anything sharp that can cut you or the line, have a functioning closing clasp if applicable, and should be free from damage and wear. All other winch accessories like covers, bags, shackles, tree savers, etc., make sure they are clean and free from anything that can harm you or the winch when in use.

If you feel uncomfortable doing any maintenance, or are unsure if something really is a problem, then find a properly trained winch person in your area for help, or contact the winch company for further instructions.

Other Articles That May Interest You:

How To Tension Your Jeep's Synthetic Winch Rope