You may think that new winch, or suspension lift, are the most important parts on your Jeep. But think about it for a minute. Neither one can prevent an accident. Right?

What about tires? Sure, they are important, however they are just the rubber connecting you to the road.

No, arguably the most important thing on your Jeep is the brake system. After all, what else is going to keep you from accidentally hitting that Prius crawling along in the left lane? Or stop you from sliding all the way down a rocky slope, possibly smashing that winch or damaging the suspension.

So when your brake warning light comes on, and your brake pedal seems way more spongy than normal, it is certainly wise to address the issue.

And one of the first things to check is your Jeep’s master cylinder.

This part is considered the heart of the brake system, and performs a number of important functions. The master cylinder holds the brake fluid, generates hydraulic pressure and feeds that pressure to the front and rear brakes. Should something go wrong, such as a damaged seal between the master cylinder and the brake booster, or a leak in the valves, then your brake system can quickly lose pressure—causing your brakes to be ineffective. Needless to say, that is not a good thing.

The quickest way to know you have a master cylinder issue lies right with that brake pedal. Normally, if you press and release, the pedal will return to its normal position almost instantly when you release. But if the pedal sinks all the way to the floor when you press, and pretty much either stays there or takes its time moving back to normal, then it is a good bet there is a problem with the master cylinder.

Now, keep in mind, if you are feeling like the pedal is somewhat spongy yet you are still able to stop as normal, then there may also be air or a fluid leak in the brake lines. That is what makes determining brake issues a bit tough. So if there is still some pressure in the pedal, then it is always a smart move to do a thorough inspection of the lines.

However, when the pedal pushes to the floor with no response after you release, well, it is almost a sure thing there is an issue with the master cylinder.

Once you’ve determined that your master cylinder is the problem, getting the part replaced is obviously the next step. But unlike, say, a front bumper or headlight, you can’t simply disconnect and pull the old one off, and then reconnect a new one.

No, you need to first fill the new one with brake fluid, and then bleed air from it, just like you do with the Jeep's brake lines once new brakes are installed. The process is a bit different, but the end result is the same—fluid only and no air.

The easiest way to do this is to bench bleed the new master cylinder prior to installation, which makes for a nice DIY project.

Sure, you can take it to a shop and have the part installed, and then quickly bled with vacuum pumps, but you can also save yourself some money and learn a few things in the process.

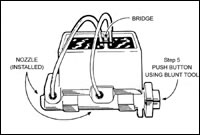

The first step is to take that master cylinder and place it in a vise by the mounting ears (flange); not the body.

Once you have it solidly in place, then take some pieces of medium size brake lines (18" or so) and securely attach to both the front and port fittings. You can also purchase a bench bleed kit that will include these lines, as well as fittings and a retainer clip. Arrange the lines so the non-fitted ends are placed into the top reservoir opening on either side of the wall. This is where the clip comes in handy to keep those lines in place.

Now, make sure to consult your owners manual for the correct type of brake fluid. Once you have that bottle ready, break the seal and fill the reservoir almost to the top—making sure both those brake line ends are fully submerged in fluid. These must also stay submerged through the whole bleeding process.

As long as everything looks good, slowly press in the piston and release. Repeat this several times. You’ll see fluid traveling through the brake hoses and back into the reservoir, but you’ll also see air bubbles as well.

The key is to keep pushing, and releasing, the piston slowly until air bubbles no longer appear in the brake fluid. You may need to do this several times before the bubbles disappear.

When all those air bubbles are gone, and only clear fluid is flowing, then you can mount the master cylinder to the Jeep—taking care not to let any fluid leak during installation as brake fluid can be corrosive to your Jeep’s paint. It may help to have some shop towels handy to ensure protection.