by Scott Ammerman

Senior Torque Correspondent

Welcome to Purpose-Built, where we take a deeper look at Jeeps that were customized for a very particular reason. When “off the shelf” only gets the job half done, these are the durable trail monsters made to go the distance and beyond. They aren’t built in huge shops for piles of cash, but created instead by regular folks with a lot of forethought and mechanical skill.

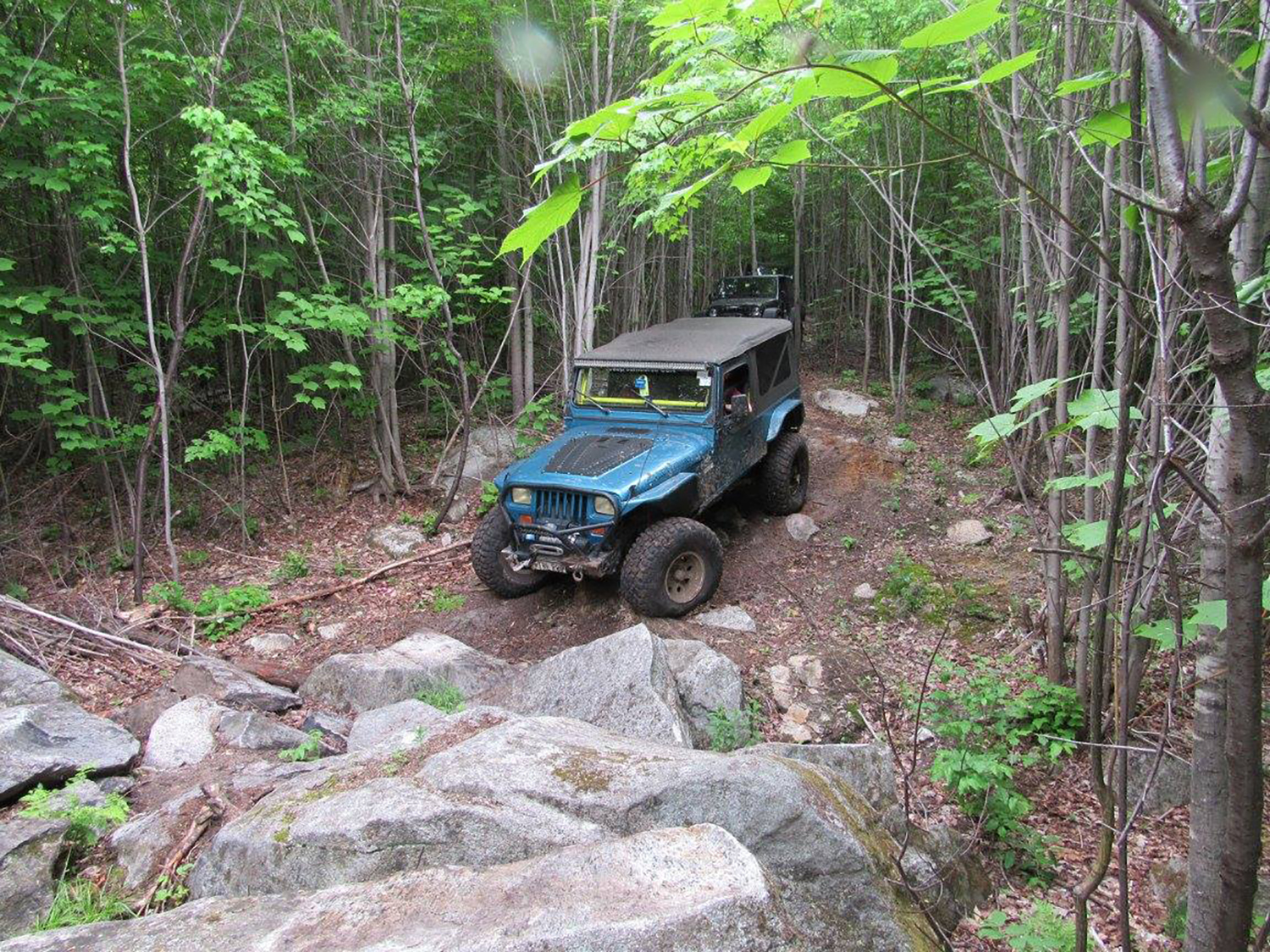

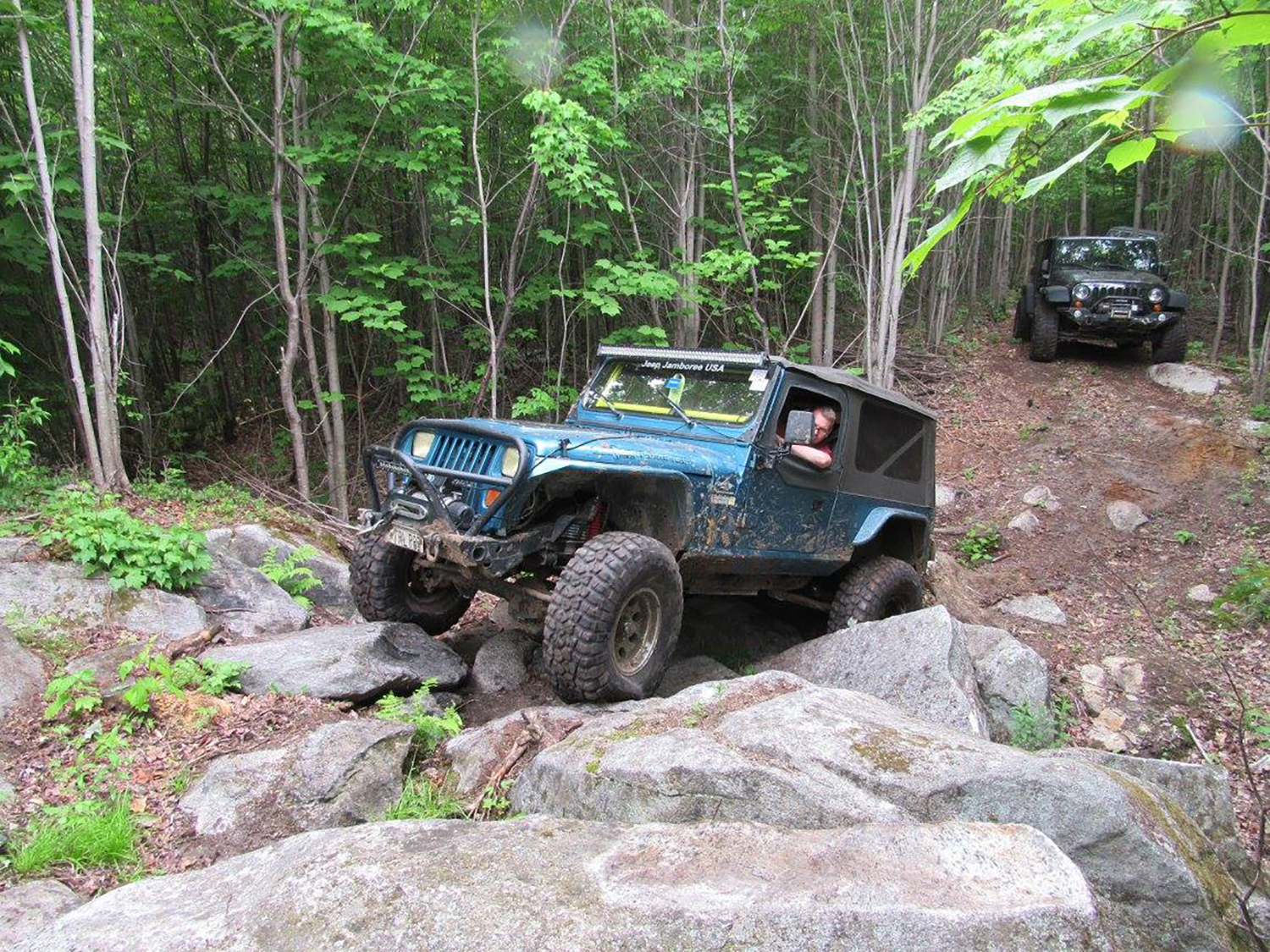

In our first installment, we’re going to take a look at this Wrangler YJ Unlimited built by Corey Ferguson of Glenburn, Maine. At the 28th Maine Mountains Jeep Jamboree, he was one of our guides on Dragon's Tail — right behind us in the trail group. I took an interest in the vehicle and poked my head under it a few times because things just didn’t quite add up.

First of all, Jeep never produced a YJ Unlimited. The original Wrangler Unlimited (designated LJ) was introduced as a stretched variant of the TJ model in 2004, and was only produced until 2006. But this was clearly a YJ body (as indicated by the square headlights), which ceased production in 1995. However, the body of this one is much longer than a factory YJ — its 104.5-inch wheelbase is right in that sweet spot.

Also missing from the YJ configuration were leaf springs, as this Jeep sat atop coils on all four corners. These corners were also stuffed with 35-inch tires and gave the vehicle worlds of flex.

Photo credit Jessica Marsh

So, needless to say, I was intrigued. After seeing how it handled one of the two most difficult trails that day, I sat down with Corey to get more details on this unusual build.

“My 1993 Jeep Wrangler started as a 4.0-liter AX-15, five-speed manual,” he said. “I purchased it locally from a Craigslist ad from a motivated seller in 2011. It was extremely beat up and rusted, and I had intended to do some quick repairs and sell it.

"At the time I was driving a 2007 JK Unlimited on 37's. Because my needs changed, I sold the JK soon after buying this Jeep to buy a Cummins crew cab. Being Jeepless, ideas began swirling in my head as to what my next build would be. I wanted something unique and originally thought about building a truck out of this rusty YJ. We have a young son, and as much as I liked the truck idea it just wouldn't be practical.

"Then I began to think about stretching it into a YJ Scrambler, but I didn't like the rear overhang and wanted a full soft top that wouldn't look out of place.

“I started doing some reading and stumbled upon a build on a Jeep forum where someone had stretched a YJ to the same wheelbase as an Unlimited. That really resonated with me, and I knew what I wanted to do with mine. I found a soft top from an LJ in the local for sale ads, ordered the LJ belt rails from my local Jeep dealer. I found an LJ roll cage down in New Hampshire for sale. The build really started to take off.

“I realized pretty quickly that the YJ frame was way beyond repair and began looking for a replacement. A local Jeep friend had just replaced the frame under his TJ due to rust where the rear upper control arms mount. He offered to give me the frame. I snatched it up and had originally planned to convert it to work with my leaf springs. Having owned many YJs, TJs and a couple JKs up to this point, I knew that I would be happier with coils and began gathering what I needed to keep this coil sprung.

“The build stalled, as my builds often seem to, and in August of 2012 I entered an online Facebook contest for a Maine Mountains Jeep Jamboree ticket and won. This was so exciting, as I had always wanted to attend a Jamboree. The only problem? My Jeep was in pieces scattered inside and outside my garage.

“I had about 6 weeks to complete the build. No problem right. Well my wife was pregnant with our second son who was due in mid-September. I spent every waking minute working on the jeep. We had our son on September 15 — the week after I sprayed the paint on the Jeep. It's a miracle I'm not divorced. Long story short, I completed the assembly with a day to spare.

“Drove the Jeep to work on Wednesday, that night I loaded it on the car trailer and hauled it to the Jamboree the next morning.”

A mix of good and bad luck was still in store at the Maine Mountains Jamboree, however. Corey trailered the Jeep to Bethel, but it was now having trouble running at all, and hardly had any power. Luckily, he was acquainted with one of the trail guides at the Jamboree; Skip Colson.

“Skip graciously offered to let me drive his Jeep for the Jamboree while he guided,” Ferguson said. “Even after losing a part of his finger in a freak accident on the trail that day, he told me to continue on with his Jeep and have fun. We have been great friends ever since. He is one of the best people I know — and tough as nails.

“Driving Skip’s Jeep was a life changing experience for me. I had owned and built nearly 20 Jeeps before this experience, and I thought I was a serious off-roader. Turns out I had barely scratched the surface.

Photo credits: Jessica Marsh

“After seeing what a well-built Jeep was capable of, I really changed my ideas of what my Jeep should be. It was at that point, with a clear focus, that my Jeep began a transition into a purpose-built trail rig. At that time, the Jeep had all the body armor, which I thought I would never scratch, and the lift and tires. The winch on it had been on four other Jeeps and only used a handful of times. I hadn’t sorted out lockers or heavy duty steering components quite yet either, but the skeleton was in place. Now the real work could begin.“

Current Build list

Body/Frame:

- YJ body stretched 15 inches, TJ frame lengthened at rear arches

- Both side rocker panels with home fabricated 3/16-inch steel rocker armor

- Home fabricated 3/16-inch steel corner armor, with homebuilt high line tube fenders and flush mount factory tail lights

- Home fabricated front high line tube fenders

- Raked back factory grille

- Poison Spyder Hood Louver

- CJ-7 tailgate

- Factory sport bar from 2006 LJ with additional fabricated supports for improved strength

- Home built front and rear bumpers with recovery points

Suspension and steering:

- Metalcloak 3.5-inch coil springs

- Skyjacker Hydro 7000 Front and Rear shocks

- Home fabricated rear dual triangulated 4-link suspension with Currie Johnny Joints on all ends of links, custom fabricated frame side mount brackets

- Daystar 1-inch Polyurethane Body Mount Lift Kit

- Upper coil buckets relocated for best suspension geometry

- Factory TJ rear sway bar, no front sway bar or steering stabilizer

- Front suspension is off the shelf, aftermarket TJ adjustable lower control arms purchased used: unknown brand, factory uppers

- Dodge Durango steering box

- Gen Right Offroad TJ chromoly tie rod and drag link

- Gen Right Offroad TJ heavy duty front track bar

- Teraflex High Steer Passenger Side Steering Knuckle

- Derale Performance Economy Power Steering Cooler Kit

Engine, Transmission and Driveline:

- Rebuilt 4.0-liter inline 6

- Original AX-15 manual transmission removed, upgraded to Cherokee XJ AW4

- NP231 transfer case with Advanced Adapters 1350 Slip Yoke Eliminator

- Drive shafts built locally, he also carries spares (old damaged shafts)

- Brown Dog Offroad 1-inch lift motor mounts

- Custom belly up transmission mount/crossmember and skid plate

- Volvo 2-speed electric radiator fan and relay assembly

- Auxiliary stack plate transmission fluid cooler

Axles, Wheels and Tires:

- Ford 8.8 rear axle from an Explorer, Detroit Locker, Artec Industries Truss, 4.10 gears

- Cherokee high pinion Dana 30 front axle, with Lock Rite lunchbox locker (he keeps replacement pins in his tool kit, after breaking pins once while out of town at a Jamboree he decided they were good to have along), 4.10 gears and stock axle shafts (has never broken one but always carries spares)

- 35x12.50x15 BFGoodrich Mud T/A KM2 tires

- American Racing Baja 15x8 aluminum wheels

- Two matching spare tires mounted on Black D window wheels (typically carry one on board and one in tow rig)

Interior and Top:

- MasterCraft Rubicon Seat with Fixed Headrest (personal history: originally used in John Hendrix of Flobuilt Conversions Build Dumpster Dive TJ Truck)

- Cherokee XJ center console and shifter (for the AW4 Conversion)

- Factory AM/FM radio that was in his first vehicle — a 1989 Wrangler Islander

- Quadratec Xtreme Value Complete CB Combo

- Rampage Products Sailcloth Trail Top Soft Top with Tinted Windows for LJ models

- Factory half doors — modified TJ uppers to work with the YJ doors

Lighting/Miscellaneous:

- Superwinch EPi 9.0 winch

- MasterPull Superline synthetic winch cable with G110 Combi Sling Hook

- Truck-Lite 5 x 7 Rectangle LED Headlights

- Rough Country single row 12-inch LED light bar mounted on bumper

- Homebuilt onboard air using an OEM Sanden A/C compressor, small one gallon Viair tank, aluminum manifold with pressure switch and high pressure blow off, inline oiler before compressor and oil/water separator after the compressor, and front bumper mounted air line coupler. It works well and didn't cost a lot to assemble. The original compressor had to be replaced with another used unit once within the last six years.

- Trail tools are stored in a Brennan's Garage waterproof tool bag (Corey swears by these, and I can see why)

At this point, Corey is very pleased with the way this rig performs, and after riding along with him on Chili Trail at the Maine Jamboree, I don’t blame him. Aside from a little tweaking from time to time, it remains trail-ready, year-round. He is planning on upgrading the front axle with a TJ Rubicon Dana 44 he found that needs some repair work.

He also has a CJ-3A getting the full treatment currently, in addition to a VW TDI power plant for loads of torque. I can’t wait to see that stomping around the mountains in Maine.

Do you own a Jeep that you've "Purpose Built" for something? Tell us your story at [email protected].