by Scott Ammerman

Torque Correspondent

Back in early May of 2018, Quadratec Content Editor Matt Konkle and I attended the Coal Mountain Jeep Jamboree event at Anthracite Outdoor Adventure Area in Coal Township, Pennsylvania. On that fateful morning, before we even left Quadratec headquarters, I noticed two bolts stuck in one of Matt’s rear tires on Project Grey Wolf. At this moment, neither of us were aware that this discovery would set the tone for the entire weekend.

My ARB Tire Repair Kit, AEV Off-Road Jack Base and Gorilla Deluxe Power Lug Wrench came in handy over the next few days, as did Matt’s portable 12v Viair Compressor, while we dealt with six deflated tires on the trail (not ours, thankfully). It was at that point I realized our basic outfitting of tire repair tools were not the final answer. After a ton of careful consideration and research, I decided on a Power Tank system instead of a portable compressor or on-board air system for a litany of reasons.

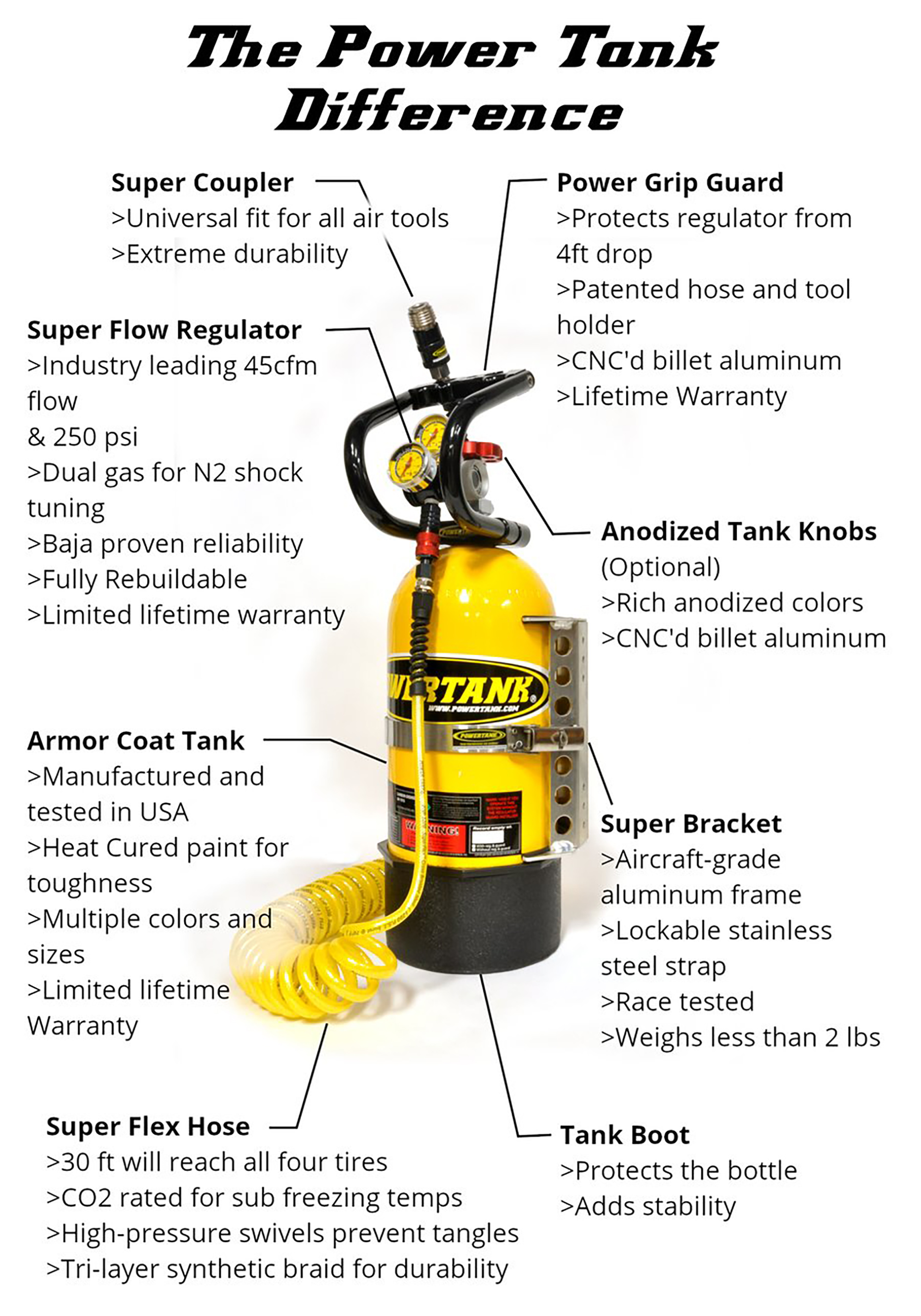

Pictured: 15lb Power Tank Package B in Candy Blue, XP400 Regulator, roll bar mounting kit.

Murphy’s Law and Science!

Refilling tires following a long day on the trails is the most common reason why people carry an air solution for off road use. Sure, some off-road parks have an air station or two that can help, but how many times are those stations actually available? It is far more likely there are several vehicles lined up in need of air, making what should be a quick job into an hour-plus wait. Additionally, that air station could be broken (or frozen) which, depending on where you are, could be inconvenient or downright troublesome. I know I’ve been caught driving several miles to a truck stop with a 40 minute wait time (plus $2 in quarters) to air back up which isn’t much fun either. Going any further than that could cause permanent damage to very expensive tires.

For those heading off-road on public land, airing up can be a challenge as well. There is most likely no air station anywhere around the trail which means someone needs to have a portable air compressor. But even those can have issues. These compressors provide steady, but slow, airflow and can overheat if used on multiple vehicles. Additionally, the glass fuse in the cigarette lighter adapter of your portable compressor may have popped at the trailhead as you inserted it, with no spares in sight. Or, your buddy’s on-board compressor that everyone in your group planned to use is suddenly on the fritz after a water crossing.

Electrical compressors also have moving parts, depend on vehicle power and can eventually fail. While turned on, an electric motor spins which drives a piston back and forth in a cylinder. This draws outside air in and increases its pressure through compression. Since compact electric compressors are engineered to save space, the tiny little pistons used to build pressure have to work really hard to squish enough air to fill up larger off road tires, and generate a substantial amount of heat and noise while doing so. Tiny little portable ones you can pick up at a rest area or auto parts store are better than nothing in an emergency, but can’t really be relied upon for constant use. Inflation times are long (some take as long as a half hour to inflate ONE tire), and many aren’t designed to run for more than a few minutes at a time. I’ve seen quite a few seize up in the gravel parking lot at Rausch Creek.

Mechanical compressor kits are available, but are not as widely used in the Jeep world. These are belt driven using your engine to spin the compressor, and are similar conceptually—they still rely on electrical compressor clutches and pressure switches to cycle on and off. Obviously, the engine has to be running for these to work.

It is not uncommon to have a compressor for a few years, only to have it decrease in efficiency as you’re using the thing. What was once a slow process of refilling tires can become even slower, while dusty or damp air can also shorten the life of your compressor system. Many premium compressor models have air filters attached to combat these two issues.

If you want to run air tools, like an impact driver or even a blow gun, you’ll need a larger capacity compressor, or an auxiliary air storage tank—all requiring an additional mounting location and air lines.

So with on board electrical compressors, you’re left with the choice of having the compressor mounted inside the vehicle (like under a seat) to shield it from harsh elements while dealing with the noise as it runs, or mounting it outside and challenging its durability. Drawing hot air from your engine compartment is also far less efficient than cooler air, and will increase inflation times.

Of course, most of these situations I have detailed are assuming you’re just trying to use a compressor in a parking lot at the end of the day. During an emergency, particularly far away from pavement, the inconvenience of a non-operational or slow compressor gets compounded drastically.

.jpg)

We waited about 10 minutes for this repaired tire to inflate to 15 psi using a compressor. The spare was already on the Jeep, and another sidewall got punctured. With two flats in a half hour, this sidewall plug (well, 7 plugs) was the only way to get it out of the woods.

Times like these really makes you wonder if there is a better way to go about this inflation business.

Luckily, this isn’t a unique dilemma. For more than 21 years, Steve Sasaki and the team at Power Tank have been assembling and selling refillable CO2 delivery systems designed to outperform portable compressors and onboard air systems. These tanks operate at pressures far beyond what your typical 12v compressor system can achieve, and this additional pressure gives you the versatility you may actually require if things go sideways when you’re out on the trails.

Power Tank's CO2 Systems offer several distinct advantages when compared to any type of compressed air system. So here are the seven reasons why I chose Power Tank:

Portability

A Power Tank mounted in a vehicle can be quickly released and taken to where it is needed. On a tight trail in a single line, this added flexibility is incredible, as shuffling around several vehicles to get air where you need it quickly can range from difficult to impossible. The Power Grip handle makes this tank super easy to lift and carry, and the various sizes give you a wide range of choices. Fully filled, with regulator and handle installed, a 5 lb Power Tank weighs around 16 lbs. The 15 lb version I selected tops out at 36 lbs. Do you have more than one trail vehicle? Well, all sorts of brackets and storage solutions are available for your Power Tank. Your RV, side by side, work truck, passenger vehicle, job site and Jeep can all benefit from your investment, rather than a permanently installed system that is much harder to swap around.

Performance/Speed

Power Tank's HP250i Regulator boasts a maximum flow rate of 45 cubic feet per minute (cfm) at 250 pounds per square inch (psi) of pressure. The optional XP400 Pro Regulator regulator increases the flow to 48 cfm and 400 psi. Most ‘top of the line’ air compressor systems (even with a storage tank) peak at around 30 psi of constant pressure, a flow below 5 cfm, and a maximum build up pressure of 150 psi. Some are much lower.

What does this mean for you? In addition to a huge reduction in inflation time (which I will detail later), you gain the ability to run air tools without waiting for a tank to build pressure. Another one of my favorite features is the silent operation, other than the sound of rushing air.

Simplicity

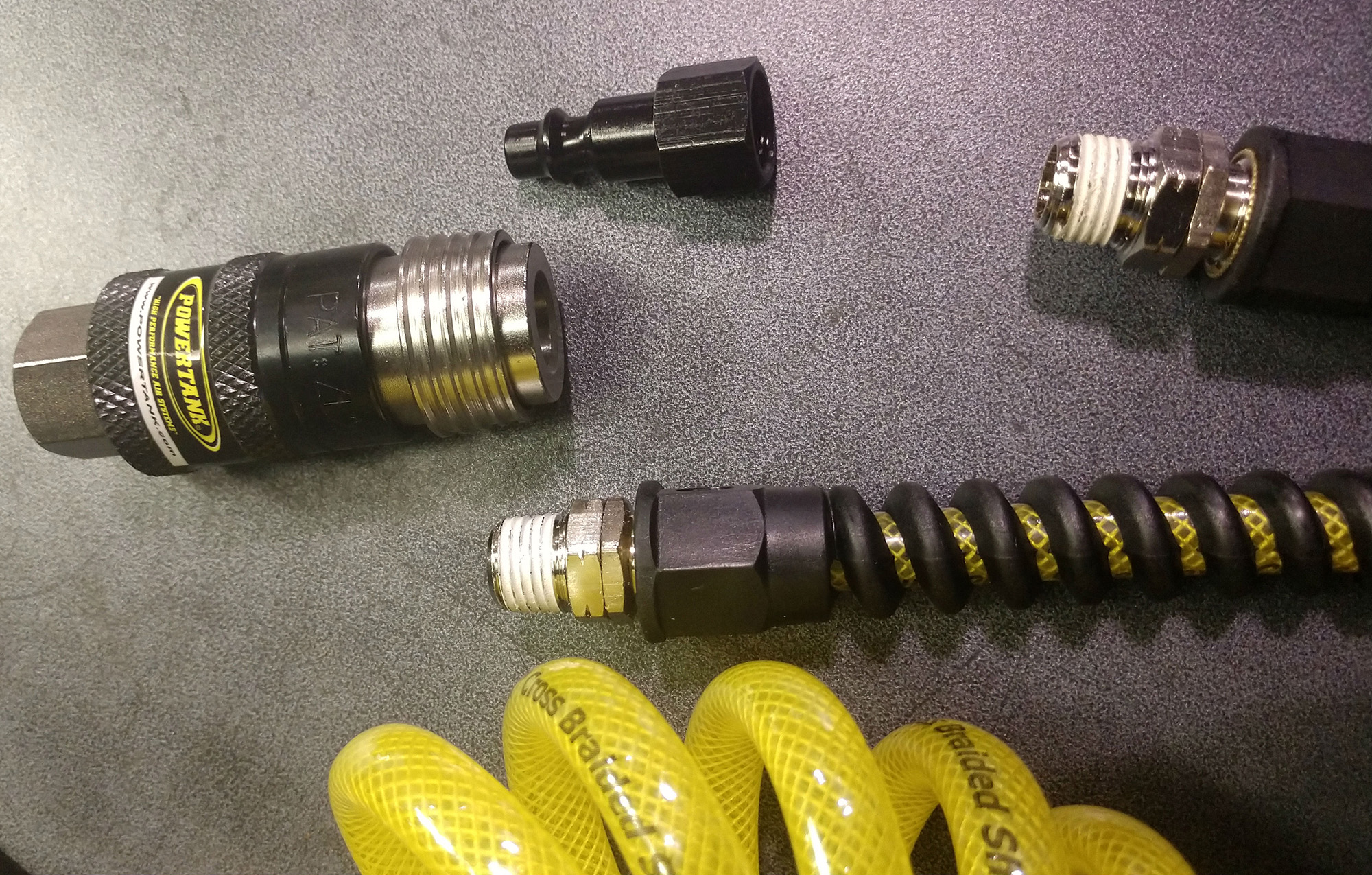

Assembling a Power Tank System is as easy as spinning together a few very high quality fittings for the hose assembly. There are no wires, fuses or sensors to worry about. In fact, there are a lot less connections than you would commonly find on even a simple on board air system—each of those junctions could potentially cause air leakage preventing tank pressure build up.

Since the pressure is already in the Power Tank, this is not an issue. You simply turn the regulator knob to the pressure you want in the air line, and the supply is there when you need it. You don’t need to worry about amperage draw on your electrical system, duty cycle (how long a compressor is designed to remain running at a time), or cooling capacity, as the pressure is already there. Also, 10 lbs of CO2 is the same as 400 gallons of compressed air, but without all that waiting for pressure to build.

Reliability

Power Tank regulators are guaranteed not to freeze clog, even when used at maximum flow in sub zero conditions. As I mentioned earlier, temperature extremes can cause havoc with compressor driven set ups, but Power Tank systems are built with features like 1200 psi boots—engineered to take both the pressure and sub-zero temperature of the compressed CO2.

Gauges in the regulators and inflators are liquid filled with silicone, while brass clip on chucks also help add unmatched temperature protection. Need to use your Power Tank in a thunderstorm or a blizzard? No problem. There are no electrical components to short out or corrode. Whether in the desert, frozen tundra or rainy summer days in the woods, these systems are engineered for the challenge.

Adaptability

With a wide array of mounting or transportation options, as well as four different available tank sizes, Power Tank has you covered no matter your air delivery needs. Several option packages bundle Power Tank’s high quality inflators and accessories with a tank and regulator assembly, and get you going with everything you need (aside from a tank fill) right out of the gate. By nature, compressed liquid CO2 has a constant bottle pressure of around 600-800 psi depending on temperature. No matter the volume of CO2 left in the bottle, this remains the same. As a result, the way to gauge how much you have left in the Power Tank is simply by weight.

Innovation

Let’s talk about the optional Power Tank Super Coupler for a moment. Do you have that one buddy who uses oddball air fittings on his tools? Not only is the Super Coupler great for relieving pressure before disconnecting air tools, but it also works with the five most common air fittings. So just about any tool you can beg, borrow or steal on the trail will work with the Power Tank setup if you have that coupler.

With a valve stem core removed, you can even reseat beads on tires up to 42”—one of the more common tire issues in an off road environment. It also happens to be one of the most difficult problems to solve due to the blast of air pressure required. Often, this kind of failure in the ‘wild’ means swapping to your spare and dealing with the carnage at a shop. But when you have a Power Tank and a few accessories on the trail, well, it can certainly save you some back-breaking work.

Longevity

Power Tank systems are engineered, designed and built in the USA to last a lifetime, and will not wear out after a few years of hard use. Power Tanks and regulators are covered by an industry-leading limited lifetime warranty against manufacturing defects. CO2 tanks of all types and sizes are required by law to be recertified every 5 years, but if your bottle ever fails the hydro test (which is done at most places that fill CO2), Power Tank will send you a replacement.

Inflators with gauges are covered for five years. More specifics on warranty coverage is available on their website, but rest assured their warranty on most items covers you for a lot longer than a one- or two-year compressor warranty. As a company, Power Tank wants you to be able to use this system for as long as you need it—they even have a regulator trade in/upgrade program for customers with earlier versions. The regulators and inflators are also fully rebuildable should they ever start to leak from wear.

Don’t get me wrong, I have nothing against compressors. I think they serve a purpose, and I’ve used them for years. I’ve even owned German cars that came from the factory with portable compressors and collapsible sidewall spare tires, and I’ve known the pain of waiting in the bitter cold for fifteen or twenty minutes for a spare tire to (maybe) inflate correctly. A Power Tank system is far more than just a regular old air tank. Every detail has been refined over the past two decades, culminating in the current generation with more performance and safety features than ever. They also have an expansive product line that I’ll summarize here:

Power Tank’s Basic Package is comprised of an aluminum powder-coated tank with nickel plated valve, HP250i regulator, Power Grip handle and 30-foot Super Flex coiled hose. A Power Flow 2 coupler and basic inflator chuck are also included, as well as a hex key to remove the handle. These are the most budget-friendly setups, and can easily be upgraded later on if desired. They come in five, 10, 15 and 20 lb sizes.

Package A adds a few items to help protect your investment—a tank boot to shield the bottom when you set it down, a cloth regulator cover and either a Super Bracket to solidly mount the system, or a Speed Bag case for more portable use.

Package B systems add a liquid filled 0-60 psi industrial quality inflator, which is hand assembled from some of the best components around. I’m really not exaggerating. These things are built to last, and stand up to the higher pressures of a Power Tank system. Analog gauges on these inflators are accurate to within two percent, and the optional digital ones are accurate to one percent.

They are also over-engineered because inflation is what Power Tank is all about, and a half-baked inflator isn’t something they’d want associated with their name. The two-foot whip is long enough to stand up while inflating, and is made of rubber covered with braided stainless steel—this keeps it very flexible at both ends of the temperature spectrum.

Which size do I want? This answer depends on many factors, and potentially can even have more than one solution. Of these variables, system dimensions and capacity are usually the most influential, but weight can also be a consideration. Keep in mind, all of these systems use the same regulators, so if your needs change, you can buy a different bottle later without having to start over.

A five-pound tank is a great size to mount in a trailered Jeep, or buggy, if space is limited, or it isn’t your only air source. If you do not have to inflate to highway pressure after each trail day, then you don’t need much gas. A five-pound tank, after all, is still the same pressure (up to 800 psi) as its larger siblings. This will give you plenty of power to run air tools and inflate several huge tires in an emergency. You can even use a Power Tank System to run ARB air lockers in a dedicated trail rig, which eliminates the need for an electrical compressor.

A 10 lb tank setup is far more popular for Jeep owners, and has a lot of great mounting options available. This tank will easily mount on a roll bar with Power Tank’s billet roll bar clamps, or with their BTS (behind the seat) Bracket on JKU and JLU models. This doubles your capacity over the five pound tank, and is an ideal size for everything up to and including 35-inch tires, several vehicles, or multiple outings between refills.

A 15 lb tank setup adds 50 percent more capacity, but is the same diameter as the 10 lb tank. I chose this size because my current tires are 35”, with a planned upgrade in the near future. I also wheel with many people who own tires on the larger side of the spectrum. I also purchased a spare tank with a Power Grip and tank boot, so a quick regulator swap (a couple of minutes at most) is all I need to be back up and running should the CO2 supply run out.

This is the Power Wrench, a versatile tool for use in removing and installing the regulator, without fear of over-torquing. It also works with 9/16 and 5/8 fittings, nitrogen shock valves and bottled beer.

A 20 lb system is great if you have the space and need to handle the air requirements of more than one vehicle, or tires that require high pressures. Trailers and RVs require higher pressures than many other tires, and can also be high volume. This would empty a lot of the smaller tanks quickly.

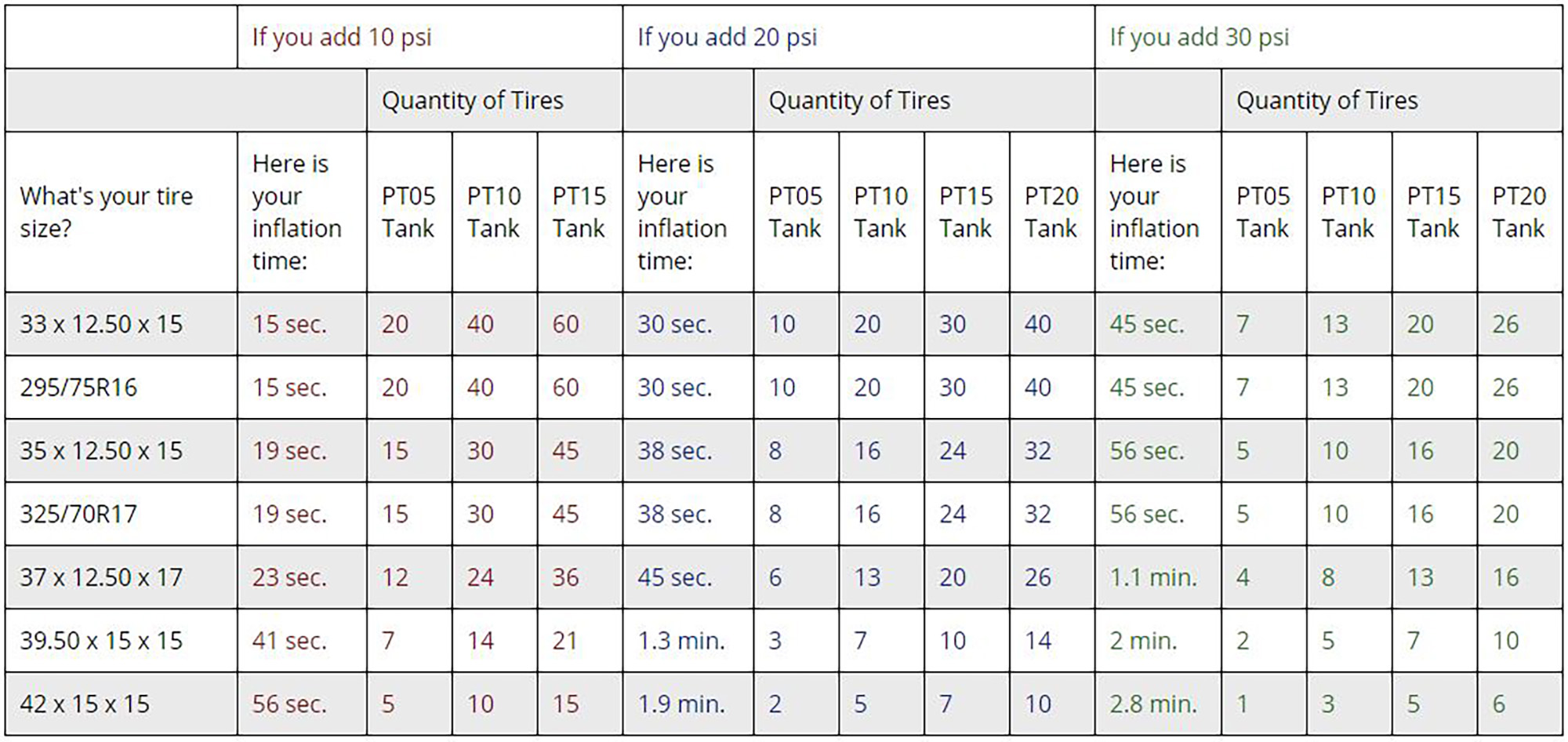

This chart from Power Tank illustrates how many tires you can fill with a fully loaded tank, and also how quickly they can be filled through standard valve stems:

Notice the inflation time for adding 20 psi to a 37x12.50x17 is *45 seconds*, and that each tank fill can be used for 20 fills (or 5 full air ups at the end of the day).

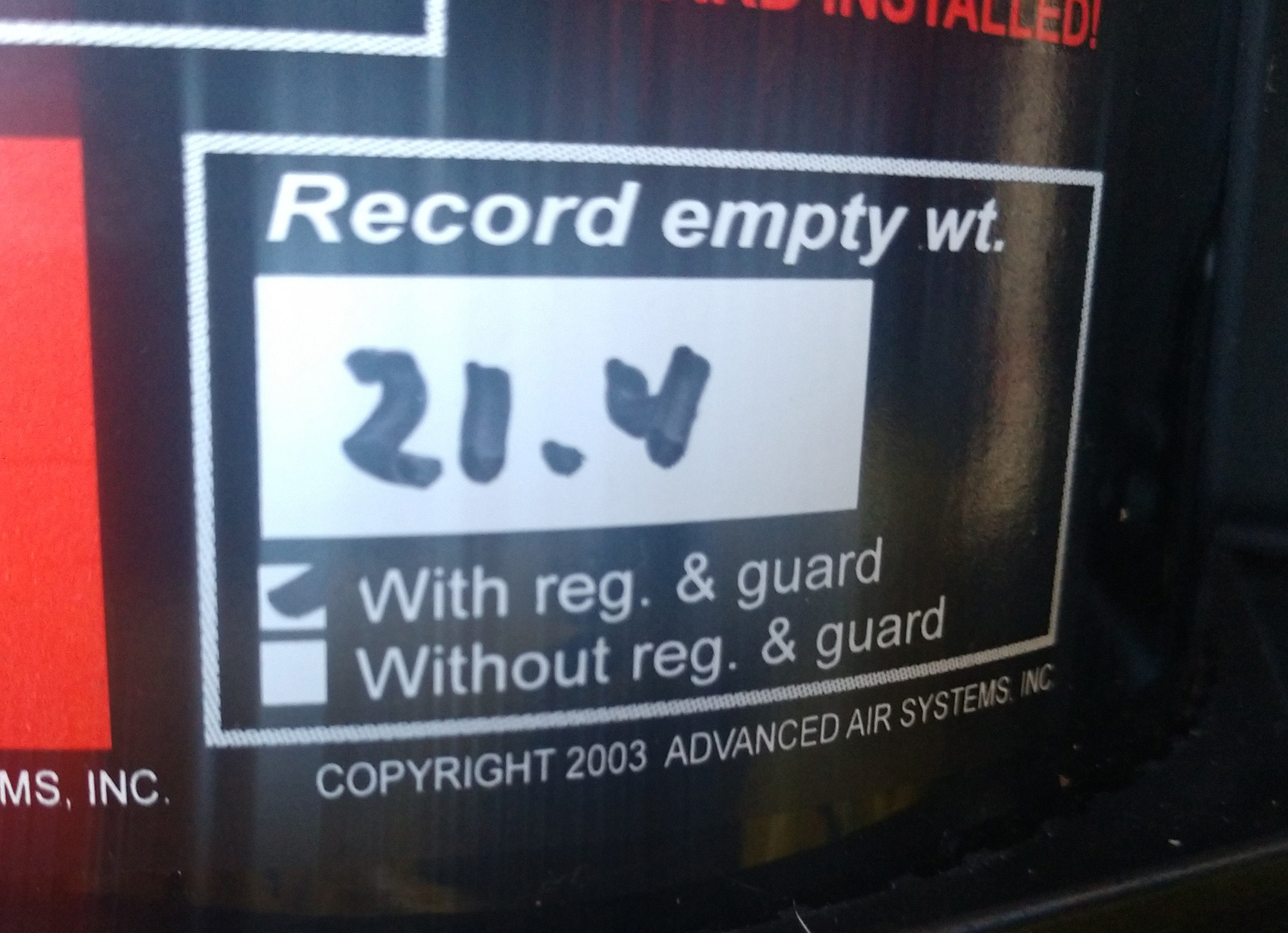

When you first receive your system, weighing it to get a baseline should be your first step. The more accurate your starting weight, the more accurate you will be approximating its remaining charge.

This is the Power Tank T-Scale, which is a lot more accurate than simply standing on your bathroom scale holding a tank. The metal hook at the end of the soft webbed strap hooks back in the triangle at the end of the handle, allowing you to weigh anything you can grip—including propane tanks for your grill or even your luggage. The backlit gauge makes it very easy to read, but a challenge to photograph. It also measures ambient temperature in Fahrenheit or Celsius.

A small spot on the tank sticker is left black to record the empty weight. I recorded mine with the regulator, tank boot and handle in place, because I would most often measure it that way to check how much of a CO2 charge I had left.

On the subject of regulators:

As I said earlier, I opted for the XP400 Regulator, with a maximum output pressure of 400 psi. I also picked up the optional Super Coupler because I wanted the ability to seat beads and work with a variety of air fittings. Additionally, with a few upgrades and a bottle of N2, this same regulator could be used to tune nitrogen shocks.

These regulators (as well as the 250 psi HP250I) are the true strength of Power Tank systems, and are even available without a bottle if your best source of local CO2 is exchange only, or if you already own a CO2 tank.

These regulators also come with the Power Grip Guard, the 30-foot coiled Superflex hose that comes with the complete systems, and your choice of coupler. With rental/exchange tanks, you won’t get the aesthetics of the Power Tank bottles, but you can still have the functionality and safety. Homemade systems, on the other hand, may save a few dollars, but are prone to freeze ups, hose bursting and valve decapitation. These situations range from inconvenient to dangerous, so a few more dollars spent on good engineering are a seriously wise investment.

The Power Grip Guard is the unsung hero of this system, and is so essential to the protection that you can’t buy a Power Tank regulator without one. You shouldn’t want to, either, as it is designed to withstand a four-foot vertical drop, while also providing vital protection in the event of an accident. Often imitated, these are CNC machined out of billet 6061-T6 aluminum, and solid aluminum rods in the USA, for the ultimate in strength and durability. They are then powder-coated black and finished off with stainless steel hardware. They even carry a lifetime warranty against manufacturing defects.

One additional patented feature is the handle’s ability to hold hose ends and a tool, which keeps that stuff out of the mud. The handle is also very ergonomic and comfortable to use, even when the tank is full. It sure beats bear hugging it to move it around.

A few notes on filling from the team at Power Tank:

You can get CO2 refills from welding supply shops, fire extinguisher servicing shops, beverage carbonics and more. It is typically best to call ahead to check pricing and to make sure they can fill your Power Tank onsite, rather than taking it to another facility to be filled offsite. Average cost to fill your Power Tank can be anywhere between $15 to $30 in the US depending on your area and the size of Power Tank you are filling.

Here is Pennsylvania, I found a local fire extinguisher supply place and they were more than happy to take care of my tank-filling needs. The cost to fill my 15 lb tanks was $25 each and they were done in about 20 minutes.

Mounting solutions? They have that covered as well.

I have used this system all winter and now into the warmer months. I kept it mounted in the trunk of the Jeep using a Super Bracket bolted to a M-PAC Springtail drivers side rack, in approximately the same place where Powertank’s BTS Bracket would mount. This is the ideal spot, in my estimation, for a JKU or JLU Wrangler. It doesn’t get in the way either, as most of the bracketry takes up unusable space.

The Super Bracket can easily bolt to any flat surface, or optional roll bar clamps can easily attach it to the rear section of a Wrangler roll bar (this is my plan with a soft top in nice weather). Check the overall tank dimensions for the best mounting solution in your Jeep. The lockable bracket can also be mounted to the outside of your vehicle and a padlock can be used to prevent theft.

So how well does the system work?

In a single word, flawlessly.

I’ve been using the Power Tank for several months now, and the only concern is how much CO2 is left in the tank. Everything else works exactly as it should, and hasn’t had even the tiniest hiccup or freeze clog in my testing. I even deflated a 35” tire in the snow (ambient temperature about 10 degrees Fahrenheit) and quickly inflated it to see how it performed in the cold. No sign of freeze clogging or slowing down at all.

Anyone who has ever used a can of compressed air knows how quickly that can gets cold when you spray it for a while. This same thing happens when much larger volumes of CO2 are released from a tank, and off-brand low flowing regulators will ice up quickly, leaving you without a source of air. As I said before, Power Tank’s regulators are guaranteed against freeze clogging, and were designed from the ground up to prevent this issue.

So, not having to wait for a compressor to build pressure, or fill an on-board air tank, is great. Also, ever have a part you need to inspect or repair that is covered in mud, sand or grease? I have, and that’s why the Power Tank High Pressure Aluminum Blow Gun is easily one of my new favorite toys. It really makes getting mud out of things like a cooling fan much, much easier—thereby making trail repairs easier as well.

Tire inflation times are remarkably improved (as advertised) with this set up, and right in line with Power Tank’s inflation chart. Being able to inflate two Jeeps worth of big tires in less than five minutes is unreal—especially fighting winter temperatures involving 15 degree wind chill. If you wheel in the winter, then you will definitely love this benefit. We used about ⅓ of the 15 lb charge on this trip, (5.2 lbs total) and can easily get a second trip with the same eight tires while still having plenty of air for emergencies.

I’ve found other uses for the Power Tank too, including cleaning out dusty electronics and rescuing people stranded in parking lots.

I would absolutely recommend a Power Tank system to anyone considering on board air. For just a little more money over a compressor, you can have something incredibly reliable that will work easily with the vehicle you have now, while having the ability to smoothly swap into anything else you’ll purchase in the future.