Around the clock overhauling, major retooling and the persistent hum of heavy machinery. That is the way of life right now for thousands of workers at Fiat Chrysler Automobiles’ Toledo, OH., Assembly Complex as work intensifies to get the place ready for the next generation Jeep Wrangler JL.

According to the Toledo Blade which was invited to a small media gathering Thursday, work is currently on schedule for the vehicle’s November 13 production start date.

But it has not been easy.

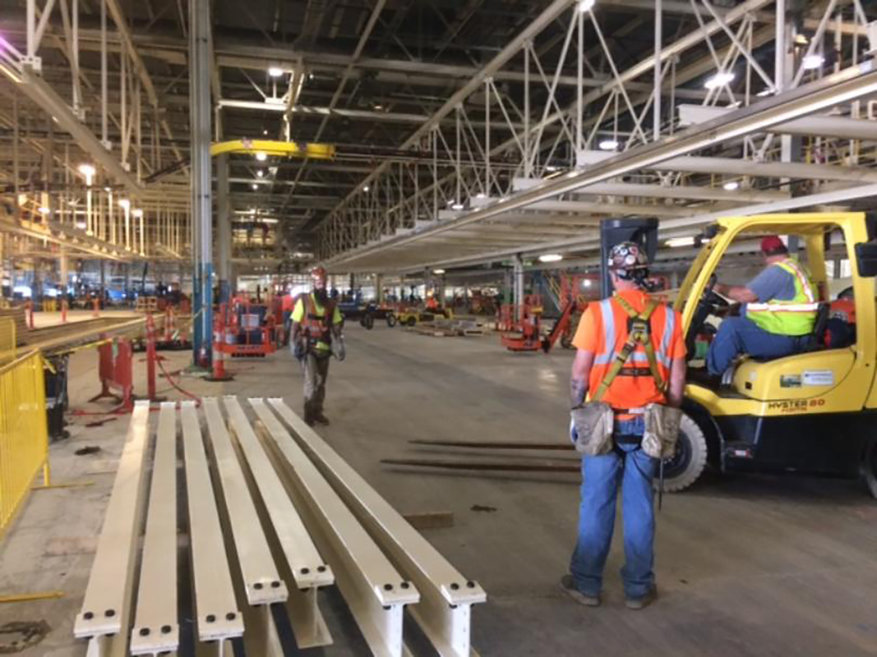

Since the last Jeep Cherokee rolled off the line on April 7, construction crews consisting of more than 2,000 workers have gutted most of the plant floor to make way for new conveyor systems, tooling, and robotics necessary for building a new Wrangler. Hundreds of thousands of man-hours have been logged already, with several months still remaining.

"With such a short time frame, it's an hour by hour schedule for development and execution,” said Plant Manager Chuck Padden. “We have a truly great team. We have wonderful engineers designing the vehicle and we have great people here in the plant as well. It is satisfying to watch it all come together. We know there is a lot of work ahead, but we are ready to continue taking on the challenge"

FCA’s investment in the workforce, as well as the plant, has been significant with the company pumping more than $700 million into this transition. Most of the plant had to be entirely cleared out and rebuilt from scratch because of the different way the new Wrangler will be built.

“At one point you could see from one end of this building to the other with the amount of demo that was going on,” Padden said.

The Cherokee, which will soon relaunch from FCA’s Belvidere, Ill., Assembly Plant, is a unibody vehicle - meaning the body and frame are essentially one single unit upon which everything from the suspension and engine to doors and seats are mounted.

The new Wrangler JL will continue as a body-on-frame vehicle, which mates a body to a separate chassis which is built with the engine, transmission, suspension, and other key components.

“It may seem simple, but basically you're almost going from building a car to a truck,” Padden said. “The frame is built separately from the body so the entire (assembly) process changes. The components are very different.”

The Blade reported FCA has already built 200 JL prototypes so far for testing around the country, but none were visible Thursday during the Toledo facility tour.

Once production ramps up for the new Wrangler, the company does plan to keep building the current JK Wrangler through March 2018 in another part of the plant, which has not been affected by the construction.

”There's a lot of activity there,” Padden said. “While all (this overhauling) is happening, we continue to build the current Wrangler in our south building. We crank out more than 800 of those every day of the week."

Officials with Fiat Chrysler told The Blade work on the Toledo Assembly Plant has included hauling away 920 truckloads of scrap material, installation of 717,000 pounds of steel as well as removal of about 4,800 tons of steel to be recycled. For the new conveyor lines, crews dug out significant sections of the floor, installed the equipment, added 40 new sealing robots and poured 4,000 yards of new concrete.

“From the technology standpoint here, there’s nothing brand new, never been used before, but some of this is brand new to Toledo and some of it is bigger, faster, better, than where the applications have been in the past,” Padden said.

One interesting addition will be adaptive lighting in the final inspection part of the paint shop.

“There’s new technology there that will actually adjust the intensity of the inspection lighting depending on the color of the car going down the line,” Mr. Padden said.

As far as the new Wrangler JL, FCA officials did not touch on any new specifics or announce an official unveiling date Thursday. Current speculation is the vehicle will have its release later this year at the Los Angeles Auto Show.

However, Padden told The Blade the Wrangler JL will be worth the wait for customers.

"The vehicle is absolutely beautiful. The customer will be thrilled when they see it,” he said. “This is going to be the biggest thing to roll out off the Toledo lines since the first Wrangler back in 1941, and we're all thrilled to have a hand in it!"